The Thermal Spray & Cold Spray Experts

Our industrial coating services are ideal for a broad range of applications in almost every industry. We work hard to create customized thermal spray and cold spray solutions for your unique challenges. Our thermal spray/cold spray capabilities include:

- HVOF Coatings

- Flame Spray Coatings

- Hard Coating Surfacing

- Roll Coatings

- Plasma Electric Arc Spray

- Plasma Transferred Arc Welding

- Electric Arc Spray

Because our industrial coating services are custom specified to your project, you can count on superior protection for and exceptional performance from your coated components. We will work with you to develop and outline procedures to match your defined specifications.

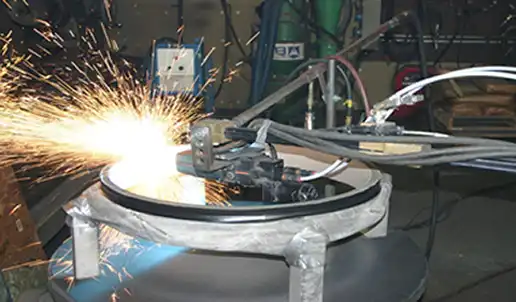

Seal surfaces on rotating components may require a wear resistant surface against a seal material made of rubber, composite or metal ring to function in a multitude of applications. Corrosive, hard particles or friction along with--

Seal surfaces on rotating components may require a wear resistant surface against a seal material made of rubber, composite or metal ring to function in a multitude of applications. Corrosive, hard particles or friction along with--

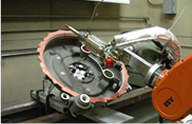

Rubber and Polyurethane Rollers