Current News

-

Hannecard Roller Coatings-ASB Industries Exhibiting at the AIST Booth 1445 in Columbus May 6-9, 2024

(Mar 12, 2024)The AIST Exposition features the latest technologies in iron- and steelmaking from all over the world. With more than 500 exhibiting companies, you'll have the chance to meet and network with the best in the iron and steel industry. Innovation and excitement can be found up and down every aisle with specialists at the Hannecard Roller Coatings booth-

Hannecard Acquires Revamo-A focused Thermal Spray Service Company in the Netherlands

(Feb 17, 2024)Hannecard, Belgium, announces the acquisition of Revamo, a company founded in 1942 in the Netherlands. Thermal spray services include combustion---

Hannecard Aquires Second Company-Sunny California

(Aug 29, 2023)Imperial Rubber Products, Inc. has joined the Hannecard Group. Imperial Rubber Products, based in Chino, California, is now an integral part of the Hannecard family. With a prime location just 35 miles from the city of Los Angeles, this strategic acquisition expands----

Summer Company Gathering Highlighting Honors

(Jul 5, 2023) Pizza, Chicken and salad were served to all of HRC to take a break from rigorous schedules. With weather cooperating with only a slight haze over Ohio from the Canadian fires, a special highlight with Gary Baker, having the highest years of service to present four important people achieving longevity---

Pizza, Chicken and salad were served to all of HRC to take a break from rigorous schedules. With weather cooperating with only a slight haze over Ohio from the Canadian fires, a special highlight with Gary Baker, having the highest years of service to present four important people achieving longevity---

Saddle for Roll Contour Profile Measuring

(Jan 23, 2023) With your unique requirements our company continues to look at our current services to offer many options -surface modifications for both wear resistant thermal spray coatings and conveying rolls utilizing rubber and polyurethane roller coverings. Our company roots are providing wear resistant and rebuilding techniques using thermal spray technologies--

With your unique requirements our company continues to look at our current services to offer many options -surface modifications for both wear resistant thermal spray coatings and conveying rolls utilizing rubber and polyurethane roller coverings. Our company roots are providing wear resistant and rebuilding techniques using thermal spray technologies--

Chirag Raval Joins Hannecard as Key Thermal Spray Specialist

(Aug 27, 2022) Mr. Chirag Raval joins Hannecard Roller Coatings, USA as a key person who will lead Thermal Spray activities with process development and key quality for the entire Hannecard worldwide locations. HRC, a key acquisition by Hannecard brings a long history as a world leader in thermal spray and cold spray technology---

Mr. Chirag Raval joins Hannecard Roller Coatings, USA as a key person who will lead Thermal Spray activities with process development and key quality for the entire Hannecard worldwide locations. HRC, a key acquisition by Hannecard brings a long history as a world leader in thermal spray and cold spray technology---

High Performance GTV HVOF Equipment Coming to HRC-ASB

(Aug 13, 2022)

Hannecdard-ASB is upgrading thermal spray equipment focused on high performance HVOF technology with installation of state-of-the-art K2 HVOF System from---

Monkal Polyurethane Roller Coverings

(Jul 18, 2022).jpg) Polyurethane equipment has been commissioned and operational. With materials on-site, our equipment manufacturer worked with our Hannecard technicians to operate equipment with technical detail from equipment operations to handling materials—

Polyurethane equipment has been commissioned and operational. With materials on-site, our equipment manufacturer worked with our Hannecard technicians to operate equipment with technical detail from equipment operations to handling materials—

Maidan Voyage Joining Continents

(Aug 6, 2021)

The first 40'HC container for the main materials, mixtures and tools is leaving Hannecard Belgium today to reach Hannecard USA (HRC) in Barberton, Ohio, USA--

Hannecard HandyCoat® Explained at the IMDPA Conference for Metal Can Decorators

(Jun 11, 2021)Related to the Can processing industry, Hannecard Roller Coatings will be attending the IMDPA Conference presenting HandyCoat®. This Conference will be showing the latest developments in metal decorating and packaging technology in Oak Brook, Illinois, USA -October 6th-7th, 2021. The HandyCoat® System is the innovative coating wheel for the beverage canning industry--

Hannecard New Processing Facility

(May 26, 2021).jpg)

Progress continues for the new Polyurethane and Rubber Processing facilities with construction including electrical, cranes, structure and all process equipment arrival. New equipment including extruders, polyurethane process equipment--

ASB Industries Integrates with Hannecard

(Jan 15, 2021)

ASB Industries and Hannecard are pleased to announce that both companies joined forces on the 15th of January to operate under the name Hannecard Roller Coatings, Inc.. ASB industries will be able to benefit from Hannecard’s worldwide expertise and R&D and at the same time Hannecard will expand ASB's recognized---

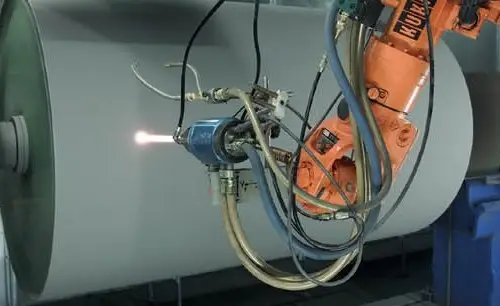

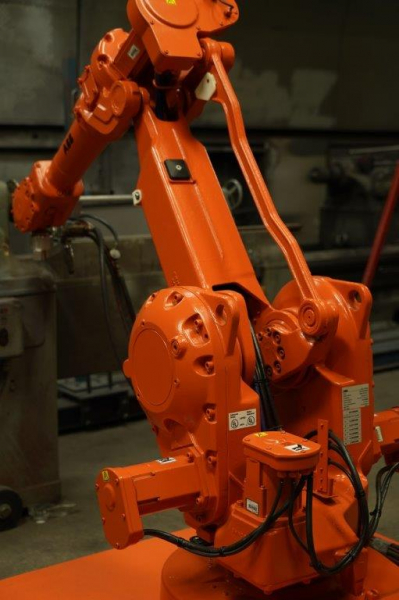

New Addition to our Robot Family

(Oct 5, 2020) ASB is at the beginning stages introducing a new thermal spray ABB robot manipulator having a small footprint giving ASB further flexibility using process fixtures that are customized and adapted to your--

ASB is at the beginning stages introducing a new thermal spray ABB robot manipulator having a small footprint giving ASB further flexibility using process fixtures that are customized and adapted to your--

ASB Industries Volunteer Support for North American Cold Spray Conference at IMAT

(Jul 28, 2020)The North American Cold Spray Conference now postponed until 2021 wil now be held with IMAT in St. Louis--

Upgrade to our Cold Spray Nitrogen Gas System

(Feb 13, 2020)

The main process gas for cold spraying is nitrogen. Critical particle velocity is required for physical build-up--

Thermal Spray Conference Presentation In June 2021

(Feb 3, 2020)

The following Abstract describes the postponed presentation by ASB's Dr. M. Daroonparvar at the ITSC in June 2021 located in Montreal. Current cold sprayed commercially pure (CP)-Al coatings on Mg alloys lack--

ASM Fellow Recognition

(Nov 18, 2019) ASB Industries has been an active participant in the Thermal Spray Society and as an outcome of this involvement, Charles Kay was recognized as an ASM Fellow --

ASB Industries has been an active participant in the Thermal Spray Society and as an outcome of this involvement, Charles Kay was recognized as an ASM Fellow --

New Horizontal Boring-Milling Machine

(Aug 13, 2019) A new Horizontal Boring Mill was recently installed and commissioned at ASB Industries. The machine installation was placed on an existing--

A new Horizontal Boring Mill was recently installed and commissioned at ASB Industries. The machine installation was placed on an existing--

Director of Research & Development Notes

(Feb 4, 2019)Dr. Reza Daroonparvar, Director of Research and Development, published works and technical contributions that support ASB Industries technical applications--

ASB is Recognized by ASM Akron Chapter as 70 Year Member

(Jan 2, 2019)![ASM Akron Chapter Recognition Celebration]() ASB Industries has been honored as a 70 Year member of ASM. ASB was presented the recognition plaque during the montly meeting at the Akron, Ohio ASM Chapter meeting by Mr. Lou Cskeo--

ASB Industries has been honored as a 70 Year member of ASM. ASB was presented the recognition plaque during the montly meeting at the Akron, Ohio ASM Chapter meeting by Mr. Lou Cskeo--

Three New Machine Tools Ordered with Two Installed

(Jul 26, 2018)![New CNC Turning Center]() ASB has recently installed two of three new machine tools which include a CNC Turning Center, a large lathe and on order is a CNC Horizontal Boring Mill..

ASB has recently installed two of three new machine tools which include a CNC Turning Center, a large lathe and on order is a CNC Horizontal Boring Mill..

New Polisher for Metallography Lab

(Jul 2, 2018)![Allied Polisher for ASB Metallography Lab ASB Metallography Lab]() ASB recently installed new equipment replacing an older polisher in our Metallography Lab. Working with Allied High Tech, ASB purchased a multiple specimen polisher with the newest software and hardware...

ASB recently installed new equipment replacing an older polisher in our Metallography Lab. Working with Allied High Tech, ASB purchased a multiple specimen polisher with the newest software and hardware...

Thermal Spray Presentation at ASM Akron

(Mar 23, 2018)Every Year ASB Industrusties supports Thermal Spray Night at the local ASM Akron Chapter Meeting. This year..

New to ASB Industries: Dr. Reza Daroonparvar

(Feb 20, 2018)Based on ASB history of furthering innovative technologies and material science related to Thermal Spray, Cold Spray and other surfacing technologies, Dr. Reza Daroonparvar recently joined ASB as Senior Coating Engineer...

New Plasma Electric Arc System

(Dec 1, 2017)A new Plasma Electric Arc System was recently added

![Ceramic Coatings:Aluminum Oxide and Chrome Oxide Plasma Electric Arc Thermal Spray System]() to increase spray capacity turning another ASB spray area into multi-process-

to increase spray capacity turning another ASB spray area into multi-process-

Heat Exchanger Upgrade for HVOF Processing

(Nov 5, 2017)![WOKA Chiller for HVOF Thermal Spray Process]()

ASB Industries utilizes the HVOF (High Velocity Oxygen Fuel) thermal spray process in many applications producing a high performance carbide coatings. The process utilizes liquid...

ADDITIVE MANUFACTURING BY COLD SPRAY TECHNOLOGY

(Aug 15, 2017)![Book that Charles Kay Helped Write about High Pressure and Cold Spray Applications]() Dr. J. karthikeyan will be Keynote Speaker at the AFTMME 2017 to be held from 2nd to 4th November, 2017 at SUS Group of Institutes in Tangoria, India--

Dr. J. karthikeyan will be Keynote Speaker at the AFTMME 2017 to be held from 2nd to 4th November, 2017 at SUS Group of Institutes in Tangoria, India--

University of Akron Corrosion Engineering Students Visit ASB Industries

(Apr 10, 2017)![University of Akron Students Visit ASB Industries]()

Along with a tour of ASB Industries, engineering students witnessed Thermal Spraying and Cold Spray with a highlight where students sprayed with the hand held high pressure cold spray---

ASB Industries Celebrates 70 Years; Kay & Karthikeyan Publish Cold Spray Reference Book

(Jan 1, 2017)For seven decades, ASB Industries has been dedicated to the advancement of surfacing technology. The company has developed a number of proprietary coating materials and unique coating processes that are customizable to the challenge at hand, be it improving the wear or corrosion resistance of metal parts, returning damaged or worn components to their original dimensions, or reducing friction between parts for better overall equipment performance.

2016 North American Cold Spray Conference

(Oct 15, 2016)Please join ASB Industries and Impact Innovations at the 2016 North American Cold Spray Conference at our combined exhibit and paper presentation:

High Pressure Cold Spray Technical Exchange

(Apr 15, 2016)With a recent exchange, ASB Industries and Impact Innovations met at the factory in Germany- continuing our long relationship based on providing exceptional equipment by understanding production and R&D needs within a wide variety of industries--

![High Pressure Cold Spray Impact Innovations 5/11 System]()

ASB Industries Annual Sponsorship for the ASM Akron Chapter Meeting

(Mar 20, 2016)For over 20 years, ASB Industries sponsors the local Akron Chapter monthly meeting by asking one of our valued thermal spray associates to speak about their thermal spray specialty---

![Mr. Bob Jones of Praxair Surface Surface Techologies ASM Local Chapter Meeting March 2016 Sponsored by ASB Industries]()

Just Delivered: 15,500 lb Capacity Tier 4 Compliant Forklift

(Jan 6, 2016)The pictured Mitsubishi Forklift was delivered to ASB Industries on January 4th, 2016- This equipment addition adds functionality and ease of operation as we continue to update our process and support equipment---

![15,500 lb Mitsubishi Forklift Mitsubishi Forklift with Automatic Fork Movement]()

Two New Electric Arc Systems Added to ASB Industries for Mechanical Rebuilding

(Oct 4, 2015)ASB continues to update equipment to afford thermal spray technicians to operate with improved functionality by recently purchasing two new Electric Arc Systems--

ASB Industries Supports & Sponsors Teachers Materials Camp

(Jul 24, 2015)Deborah Curtis of ASB Industries volunteered time for the week long Materials Camp held at the University of Akron. For 10 years now held in Akron, Ohio, this is one of many Material Camps across-

![Teachers Camp Sponsorship by ASB Industries ASM Teachers Camp]()

New Rotary Screw Air Compressor

(Jun 29, 2015)ASB Industries recently installed a new electric Gardner Denver multispeed air compressor-

![Electric Air Compressor Rotary Feed Electric Air Compressor]()

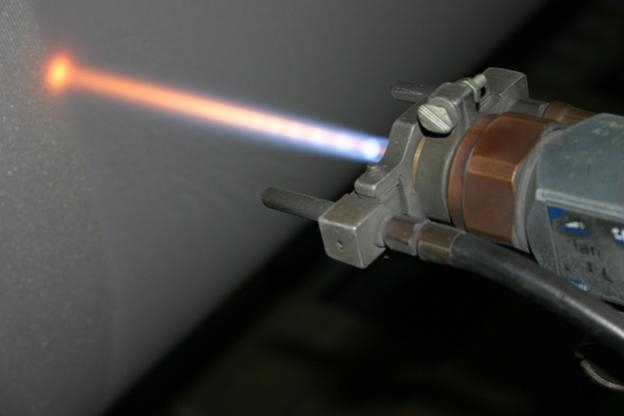

High Temperature Furnace Rolls Surfacing for the Steel Industry

(Apr 23, 2015)Furnace rolls are processed at ASB Industries with selected grinding and thermal spray procedures. Rolls are inspection dimensionally

![High Temperature Furnace Rolls Complex Crown Grinding]()

Fagor Automation to Featured ASB Industries 60" diameter Grinder Modernization

(Apr 22, 2015)Fagor Automation, headquartered in Spain with International sales and support offices will pen a product highlight feature on the installation of their Fagor 8065 Controller on ASB Industries 60” Diameter roll Grinder-

![Mesta Grinder with Fagor Controller 60" Diameter x 224" Roll Grinder]()

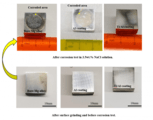

Example of Testing-Procedure Development

(Nov 4, 2014)Customer product advancements and new technology developments can cultivate ASB’s current process techniques and specifications becoming a welcome challenge to develop new materials and procedures using our surfacing technologies---

![Coupon Testing with Profilometer Surface Profile]()

Cold Spray Equipment Upgrade

(Sep 19, 2014)ASB Industries upgraded our current Impact Innovations Cold Spray equipment to the 5/11 System capabilities. This most advanced system is based on years of proven engineering, experience, reliability and performance allowing a wider variety of material spraying capabilities using

Thermal Spray Multi-Purpose Processing Room Upgraded

(Sep 15, 2014)ASB Industries utilizes a variety of areas throughout our 9 acre facility focussed on flexibility---

![Thermal Spray Processing Cell]()

Landis Grinder Modified with Upgraded Controls

(Jun 16, 2014)ASB recently upgraded our 18" Diameter Landis grinder with electronics and operator controls-

![Precision Grinding for HVOF and Plasma Electric Arc Thermal Spray Landis Grinder 18" Diameter x 144" Long]()

Cylindrical Roll Grinder Modernization Completed

(May 8, 2014)![Controller for CNC Grinding Controller for CNC Grinding]()

ASB Industries 60" Diameter x 288 long cylindrical grinder has been a key piece of equipment with consistent production for over thirty years- giving our customers options for larger roll bodies, shafts and a variety of thermal spray surfacing projects with diamond grinding media to complete demanding jobs.

Project Based Investigation of Inco 625 Cold Spray Thick Coating

(May 2, 2014)![Impact Innovations High Pressure Cold Spray Equipment Inco 625 Cold Spray Coatings]() The photo-micrograph shown are from one of ASB’s outside material test labs-

The photo-micrograph shown are from one of ASB’s outside material test labs-

ASB Develops Innovative 3D Printing & Painting Technology

(Jan 5, 2014)ASB Industries’ advanced 3D painting/printing systems have been used for the fabrication, repair, and refurbishment of parts by some of the world’s leading OEMs.

GE News: ASB Industries' 2000-2 Portable High Pressure Cold Spray Being Used For 3D Printing

(Dec 23, 2013)GE Research heavily involved in High Pressure Cold Spray research initiatives releases further information about their additive cold spray projects.

Installation of Impact Innovations High Pressure Cold Spray System at ASB Industries

(Jun 21, 2013)Successful installation of the Impact Innovations Spray System 5/8 is complete on the first day of the North American summer solstice. This fully integrated High Pressure Cold Spray System started flawlessly after approximately a few hours after the start of the installation--

ASB Industries Enters Representation of Impact Innovations

(Mar 12, 2013)ASB Industries has entered into a partnership to represent Impact Innovations High Pressure Cold Spray equipment in North America. Impact Innovations High Pressure Cold Spray System advancements combine years of knowledge and experience as the past founders of the successful line of CGT equipment.

Value of Cold Spray Processing Explained on U.S. National News

(Jan 4, 2013)Value of Cold Spray Processing Explained on U.S. National News----Please watch the following Fox news report showing the value of Cold Spray Aluminum to repair Magnesium Components. Click Here for the Video

Dr. Jegan Karthikeyan is the ‘Guest of Honor’ at the International Conference on Advancements and Futuristic Trends in Mechanical and Materials Engineering

(Nov 8, 2012)Punjab Technical University (PTU) successfully organized a three day International Conference on “Advancements and Futuristic Trends in Mechanical and Materials Engineering" on 5-7 October 2012 at the University Main Campus

New Patent Issue to ASB Industries Invention for Cold Spray Hardware

(Sep 7, 2012)Spray Nozzle Assembly for Gas Dynamic Cold Spray and Method of Coating Substrate with a high Temperature Coating- Patent US 8,192,799 B2 Issued June 5, 2012

Method of Forming Foam by Cold Spray Technique

(Aug 1, 2012)ASB Industries Research & Development division worked closey with ExxonMobil to develop metallic foam

Babcock & Wilcox and ASB Industries Celebrates 15 Years

(Jul 9, 2012)ASB Industries celebrates our 15 year association with Babcock & Wilcox Company as one of B&W Authorized Service Centers

ASB Industries Achieves FAA Repair Certification Repair Status

(Jun 21, 2012)ASB Industries recently achieved FAA Repair Station Certification using the High Pressure Cold Spray Process.

Notable High Pressure Inside Diameter Cold Spray Equipment Advancement

(Jun 3, 2012)Inside diameter spraying is a challenge for spray processing due to equipment capabilities.

High Production CGT 8000 System

(Jan 12, 2012)Demonstration Systems at ASB Industries range from the CGT 2000 Portable System to the CGT 4000 System to the newest high Production CGT 8000 System.

ISO Recertification

(Nov 18, 2011)ISO Certification completed for three year full audit. No major or minor discrepancies.

ASB Industries Supports ASM Thermal Spray Society

(Sep 20, 2011)ASB Industries has long been a supporter of the TSS-The Thermal Spray Society of ASM International. Members of our company play key roles in committees and leadership positions in the Thermal Spray Society, and we are proud to be involved with this important organization.

ASB Industries has been honored as a 70 Year member of ASM. ASB was presented the recognition plaque during the montly meeting at the Akron, Ohio ASM Chapter meeting by Mr. Lou Cskeo--

ASB Industries has been honored as a 70 Year member of ASM. ASB was presented the recognition plaque during the montly meeting at the Akron, Ohio ASM Chapter meeting by Mr. Lou Cskeo--  ASB has recently installed two of three new machine tools which include a CNC Turning Center, a large lathe and on order is a CNC Horizontal Boring Mill..

ASB has recently installed two of three new machine tools which include a CNC Turning Center, a large lathe and on order is a CNC Horizontal Boring Mill..  ASB recently installed new equipment replacing an older polisher in our Metallography Lab. Working with Allied High Tech, ASB purchased a multiple specimen polisher with the newest software and hardware...

ASB recently installed new equipment replacing an older polisher in our Metallography Lab. Working with Allied High Tech, ASB purchased a multiple specimen polisher with the newest software and hardware...  to increase spray capacity turning another ASB spray area into multi-process-

to increase spray capacity turning another ASB spray area into multi-process-

.jpg)

.jpg)

.jpg)

The photo-micrograph shown are from one of ASB’s outside material test labs-

The photo-micrograph shown are from one of ASB’s outside material test labs- .webp)