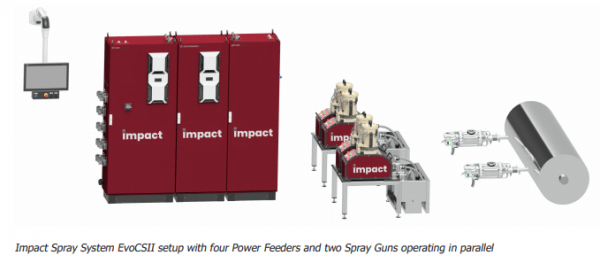

Impact Spray System EvoCSSII

The latest cold spray system from Impact Innovations is called Impact EvoCSII. All developments and experiences of the last ten years were used as the basis to design a perfectly coordinated plug and play solution. Impact Innovations achieved to offer customers consistently high quality for single part and series production based on a durable but also maintenance-friendly system architecture through intelligent process control.

Benefits of the Impact EvoCSII

Due to the parallel operation of up to four Impact Powder Feeders, the new Impact Cold Spray System EvoCSII is great for serial production. It is also possible to operate two Impact Spray Guns in parallel for double-sided coating or simply higher capacity. Thanks to a higher number of sensors, data recording and an integration in higher-level control, the process reliability increased significantly. In addition, the EvoCSII system has a modular system structure, which can also be expanded as required at a later point in time. Furthermore, the necessary interfaces for future developments have already been integrated. Additional benefits include:

- Compatibility of all existing additional components

- Generation and recording of all process data for quality assurance and documentation

- Open interface for integration in a higher-level controller

- Completely new software architecture, with a simplified and intuitive operating concept

Key Facts and System Components

- Increased nominal pressures of the individual system

- components

- Cold Spray Gun 5/8 EvoCSII → 50 bar / 800 ° C

- Cold Spray Gun 6/11 EvoCSII → switchable 50 bar /

- 1100 ° C and 60 bar / 1000 ° C

- Electronic Control & Gas Management Unit → 100 bar

- Powder Feeder → 60 bar or 80 bar

- Preheating Unit → 100 bar

- Process gas nitrogen or helium (or a mixture of both)

Cold Spray Applications

- Aerospace

- Electric Power Industry

- Electrical Engineering

- Glass Industry

Learn More About the Impact Spray System EvoCSII

Hannecard - ASB is the North American distributor of Impact Innovations’ high pressure cold spray equipment, providing sales and tech support throughout the United States, Canada, Mexico, and beyond. Give us a call at 330-551-5217 or submit a quote request today.

.webp)