Machining, Grinding & Finishing

Since every thermal/cold spray coating project is unique, Hannecard - ASB develops specific combinations of surfacing technologies and machining procedures to ensure optimal component and equipment performance. Our established in-house procedures and customer-specific quality assurance programs assure that every project meets the required specifications.

Hannecard - ASB is ISO 9001 and ISNet World Safety certified. Our thermal spray and cold spray technicians are Thermal Spray Operator Certified (CTSO), and work alongside experienced certified journeyman machinists to provide the best quality coatings possible.

To add even greater value to our cold spray and thermal spray coatings, we offer numerous secondary services. All are performed in-house to ensure quality standards and other requirements are met.

Submit your project today or contact us to learn more about our thermal spray and cold spray coating capabilities.

Secondary Surfacing Capabilities

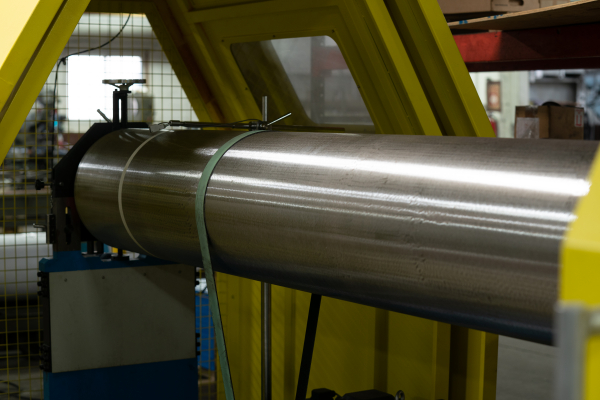

GRINDING

- 6 grinders with capacity up to 60” diameter x 288” long

- Roll & cylindrical grinding

- Equipment supports high tolerances, tapers, crowns, belting & polishing

- Diamond grinding is used to finish tungsten carbide and ceramic coatings

- Specialty polishing provides chatter free surfaces.

LATHE CAPACITY

- 9 lathes with capacity up to 78" diameter x 252” long

- Variety of tooling and belt finishing options

VERTICAL BORING MILLS

- 2 vertical CNC boring mills with 126” swing x 63” under rail

- Dual heads: turret & fixed

- 1 15.75” diameter x 21” swing with Fanuc controller and live tooling

- 2 manual mills with capacity up to 48” swing

HORIZONTAL BORING MILLS

- 1 horizontal boring mill with 60” x 135” worktable

- 1 horizontal boring mill with 43" x 47" worktable

CNC MACHINING CENTER

- 2 CNC horizontal machining centers with worktables as large as 30” x 59”

Welding

- Plasma arc welding, Plasma Transferred Arc (PTA)

- Submerged arc welding

- Delta welders

- Conventional welders

- Various positioners & turntables for fast, accurate welding

- Large 2.5 million BTU oven for post-treatment sealing/coating systems

- Two radial drills with 10’ arms

- Vertical & horizontal band saws

- Bearing pullers

- Surface inspection equipment

Discover the extensive machine-shop capabilities Hannecard - ASB offers to support complete pre- and post-treatment of all Thermal Spray, Welding and Cold Spray projects.

.webp)