Roller Covers for Coil Coating Lines

Monkal® Roller Covering

Monkal® Roller Coverings

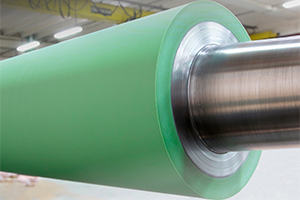

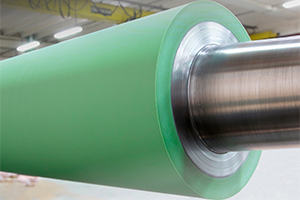

Applicator Rollers

Applicator Rollers apply liquid treatments or paint onto substrates. These unique rollers directly affect the quality of the final coated strip of your Coil Coating Line. Monkal® polyurethane (PU) solutions are renowned worldwide for their unique coating behavior, purity, and long lifetime. Specially designed for coating purposes, these covers combine extreme purity with consistent performance. Applicator Rollers with Monkal® covers are characterize by: outstanding surface energy, excellent resilience, good resistance to abrasion and edge cutting.

Applicator Roller Coating Applications

We provide applicator rolls for chemical coating (surface treatment) as well as color coating (organic and solvent based varnishing).

- Chemical Coater Rolls (surface treatment)

- Chemical Coater Applicator Rollers

- Metering Rollers.

- Find more details here: (Chemical coater applicator / metering roll - Hannecard)

- Paint Applicators / Varnish Applicators and Metering Rolls

- Prime Coaters

- Finish Coaters

- Find more details here: (Paint / varnish applicator / metering roll - Hannecard)

Monkal® Applicator Roller Covers Provide Consistent High-Quality Performances

- PU technology with double filtering for purity

- Specific formulations for color and chemical coil coatings

- Vertical casting for seamless covers

- Hardness range of 15-70 Shore A

- Surface energy up to 45 mN/m

More details here: (MONKAL® THE ONLY ROLLER COVERING ESPECIALLY DEVELOPED FOR COATING APPLICATIONS (hannecard.com) )

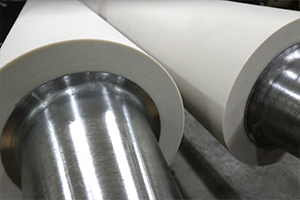

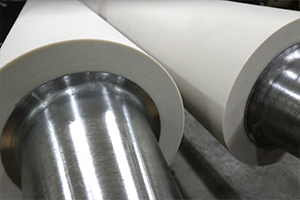

Pick-Up Rolls

We offer long lasting solutions for pick-up rollers, based on our unique thermal spray technology.

- Paint Coater Pick-Up Rollers

- Chemical Coater Pick-Up Rollers

Pick-Up Roller Cover Characteristics

- Very high density and hardness

- Excellent lifetime

Roller Covers for Cleaning and Degreasing

Most steel and aluminum transformation and coating lines are equipped with cleaning sections to remove protection oils and lubricants, preparing the strip for the next step. The success of this cleaning operation widely depends upon the performance of elastomer-covered rollers, which need to perform within specific chemical, physical and thermal conditions. The Hannecard Group offers a range of roller covering material options, which guarantee performance combined with an exceptional lifetime.

- Squeegee Rollers / Wringer Rollers – (Cleaning squeegee roller - Hannecard)

- Deflector or Sink Rollers (Cleaning sink roll / deflector roll - Hannecard)

- Carbide-Covered Brush Back-Up Rollers (Cleaning brush / polisher back-up roller - Hannecard)

Benefits of Choosing Roll Covers from Hannecard – ASB

- Maximum resistance to cutting and abrasion

- Chemical resistance to degreasing products, oils, and lubricants

- Resistance to continuous high temperatures

- Excellent surface, wringing, and steering behavior

- Special finishing for better grip and steering

- Mechanical and restorative maintenance of the roller

Rollers to Manage Mechanical Forces

The perfect transport of strip, as well as other mechanical functions, usually requires specialized roller coverings. This typically includes finishes like crowning and grooving. Hannecard - ASB has developed a range of rubber, polyurethane, composite, and carbide covers and coatings for this purpose.

- Strip Support and Table Rolls (Looper, strip support, conveyor roller - Hannecard)

- Pinch and Snubber Rolls (Pinch, snubber, pressure, drive roll - Hannecard)

- Deflector Rolls (Detour, deflector, transport roll - Hannecard)

- Tensioning and Bridle Rolls (Bridle, tensioning, stretching roll - Hannecard)

All proposed solutions have excellent resistance against mineral oils and against the most common lubricants.

Click here for detailed information – Rollers for the Management of Mechanical Forces (hannecard.com)

Choose Hannecard – ASB for Innovative Metal Coil Processing Solutions

Hannecard – ASB Industries is committed to providing all industrial sectors with the best advanced surfacing technologies. We have centered our business on innovative processes, cost-effective solutions, and high-performance results designed to support your business and production goals.

Contact us or request a quote today to learn more about our fast turnarounds, turnkey services, and other capabilities. We’re ready to create individualized solutions to provide exceptional results.

Metal Coil Coatings

Monkal® Roller Covering

Monkal® Roller Coverings

.webp)