Steel Production

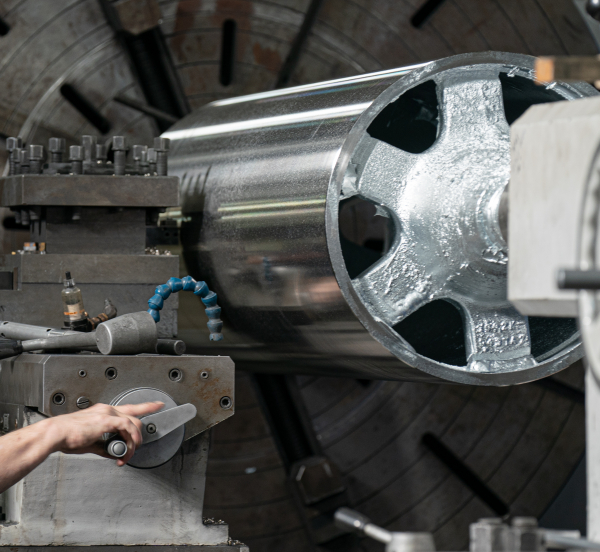

Steel Production Sink Roll

Thermal Spray Coatings and Rubber & Polyurethane Roller Coverings for the Steel Industry

The steel industry relies on rollers and other machinery for steel, aluminum, and stainless steel strip production, often in harsh conditions. Roller surfaces undergo significant wear and tear as metal strip passes through various processing phases, coming into contact with chemicals, high temperatures, high tension, and frequent line stops. Over time, these extreme conditions cause rollers and equipment to experience wear due to corrosion, thermal exposure, and abrasion, ultimately leading to equipment failure.

Hannecard – ASB's thermal spray coatings and roller coverings improve the performance and extend the life of steel processing equipment, improving production time, and positively adding to your facility operations. With our diverse array of thermal spray processes and rubber and polyurethane coverings, we can develop customized, cost-justified solutions tailored to your processing lines.

Advantages of Roller Coverings & Spray Coatings for Steel, Stainless Steel, & Aluminum Components

Hannecard – ASB's thermal spray coatings and roller coverings provide numerous advantages for treated components and equipment used in the steel industry. Benefits include:

Wear and Abrasion Resistance: Extends the life of rollers and equipment in steel processing environments by providing a durable layer of protection against wear and abrasion.

Wear and Abrasion Resistance: Extends the life of rollers and equipment in steel processing environments by providing a durable layer of protection against wear and abrasion.- Corrosion Resistance: Protects components from corrosive elements and harsh environmental exposure.

- Improved Grip: Thermal spray coatings and rubber or polyurethane roller coverings improve grip for more efficient processing.

- Thermal Barriers: Provides protection for machinery exposed to extremely high temperatures.

- Enhanced Surface Quality: Improves the performance and longevity of machinery by optimizing surface properties.

Applications: Coating Sprays for Steel Coil Rollers & Other Metal Components

Our coatings and coverings are used to provide protection and enhanced performance for a wide range of components in the steel industry. For your unique application, we will consider your OEM specifications and provide suggestions for possible improvements, ensuring you get the proper spray coatings for your requirements. Equipment and components in the steel industry that Hannecard – ASB's spray coatings and coverings can be applied to include:

- Tension & Steering: Enhance grip and reduce wear for tension and steering components like bridle sections, dancer rolls, steering rolls, and tensiometer rolls.

- Cleaning Section: Protect cleaning equipment from corrosion, extreme temperatures, and electrolytic exposure with coatings for back-up cleaning rolls, back-up coater rolls, back-up polisher rolls, grind pressure rolls, wringer rolls, and squeeze rolls.

- Furnaces: Spray coatings provide thermal barriers, pick-up protection, and wear resistance in high-temperature applications for horizontal & vertical furnace rolls, water and non-cooled furnace rolls, and seal rolls at furnace entry.

- Continuous Galvanizing: Ensure pick-up and wear resistance in continuous galvanizing equipment with coatings for sink rolls, stabilizer rolls, top tower rolls, and snouts.

- Entry, Exit & Temper Mill Components: Our coatings can enhance performance for billy rolls, deflector rolls, gauge control rolls, idler rolls, looping tower rolls, mandrel segments on entry & exit reels, tachometer rolls, measuring rolls, scrap chopper rolls, applicators, coater rolls, carrying rolls, table rollers, side trimmer rolls, snubber rollers, pinch rolls, cradle rolls, and more.

.jpg)

We have the experience and the expertise to deliver the ideal coating solution for your project. Discover more about our protective steel coatings. This assembled machined component features a polyurethane covering on a Bridle Roll used in a Strip Pickle Line.

Contact Us to Learn How Our Coatings Can Improve Your Steel Industry Components

Hannecard - ASB Industries' coating processes are designed to meet the demands of the steel industry. By improving durability and performance, our coatings extend the life of your equipment, enhancing efficiency and reducing long-term costs.

Contact us today to learn how our custom spray coatings and coverings can benefit your steel processing operations. For pricing estimates on custom orders, request a quote online. Hannecard – ASB Industries is here to provide tailored solutions for your unique requirements.

Publications:

Thermal Spray Applications in the Steel Industry

Edited By: C.M. Kay, Hannecard - ASB

ASM Handbook, Volume 5A: Thermal Spray Technology, ASM International

2013

![]()

Download article preview

PDF (131 KB)

.webp)