Thermal Spray Roll Coatings

Furnace Roll Processing

Die Penetrant Crack-Porosity Inspection

ISO Certified Inspection Micrometers

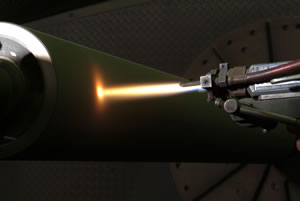

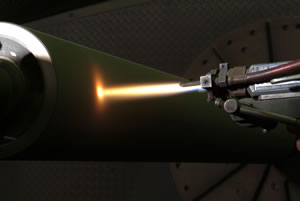

Roll Surfacing applying Pick-up Resistant Coating

Work Roll Bearing Repair

Roll Coating Services are the ideal performance-enhancement solution for a wide variety of manufacturing industries. Custom industrial roller coatings can be especially effective for operations such as high-production processing of steel or paper, both of which require unique surfaces.

Hannecard - ASB’s industrial roller coating covering solutions adds wear life and reduces maintenance needs for your critical equipment. Our roll coating processes can also be modified to meet the performance and environmental requirements of your specific application. Hannecard-ASB’s experts have the knowledge and skills to apply the custom coatings directly to your industrial roller, allowing for a seamless transition from coating to application.

Roll Coating Benefits

Thermal spray roll coating technology can be used to noticeably enhance performance for a variety of unique situations. Additional post-treatment sealing & oxide layering can be applied to further improve thermal spray roll coating performance. Our roll coatings provide enhanced performance for:

- High-Temperature Environments

- Corrosive Atmospheres

- Abrasion

- Gripping Requirements

- Oxide Debris Buildup

Roll Coating Material Options

We offer a wide range of custom industrial roller coatings material options for your unique project requirements. We provide corrosion resistant, wear resistant, and traction and release coatings that are available in the following materials:

- Carbide Coatings: Tungsten Carbide, Chromium Carbide

- Ceramic Coatings: Chrome Oxide, Aluminum Oxide, Alumina Titania, Zirconium Dioxide, Titanium Dioxide

- Plating: Hard Chrome - optional outsourced service in conjunction with turnkey roll processing

- Metallizing: Aluminum, Copper, Nickel, Stainless Steel

Benefits of Roller Coatings

Hannecard-ASB Industries inspects critical roll dimensions and evaluates substrate conditions during incoming inspection and processing times. We continue to evaluate important aspects of the condition of your equipment as the roll coating process progresses. When rolls require journal repair, including bearing and sealing surfaces, machining and the proper application of a thermal spray coating can return your roll back to its original specifications.

Hannecard – ASB’s In-House Specialty Tooling for Industrial Roller Coatings

Using our in-house inventory of specialty tooling, grinding media, and thermal spray coating materials, we will select the ideal combination for your roll coating needs. Similarly, Hannecard-ASB Industries utilizes application-specific combinations of tooling and grinding media to remove used, damaged, or worn roll coatings.

Unique finishing capabilities, including diamond grinding, are part of our turnkey roll coating services. All our processes come together to produce better-performing and longer-lasting parts.

During processing, we carefully select the most effective blast media, thermal spray powder morphology, and roll coating process technology to produce the desired surface finish for your roll coating.

Measure Surface Roughness of Rollers

Calibrated surface finish profilometers are used as one of many quality checks and are cross-referenced to your specifications. We continuously checks the surface finish of your roll coating against a variety of key surface finish measurements based on material chemistries, material hardness, and process applications.

Roller Coating Solutions by Industry

Every industry has unique application challenges that can be solved with the right roll coating. At Hannecard-ASB Industries, we provide custom industrial roll coatings and advanced surfacing technologies to the following industries:

- Steel production & processing

- Power generation & utility

- Paper & pulp processing

- Aerospace coatings

- Petrochemical industries

Contact Us for Industrial Roll Coating Services Today

For more information regarding our custom industrial roller coating solutions, get in touch with our sales team or request a quote for specific pricing information today. Hannecard-ASB Industries are the roll coating experts. No matter what your industry or application, we can provide the perfect roll coating solution.

Furnace Roll Processing

Die Penetrant Crack-Porosity Inspection

ISO Certified Inspection Micrometers

Roll Surfacing applying Pick-up Resistant Coating

Work Roll Bearing Repair

.webp)