Tungsten Carbide Coatings

HVOF Tungsten Carbide Processing

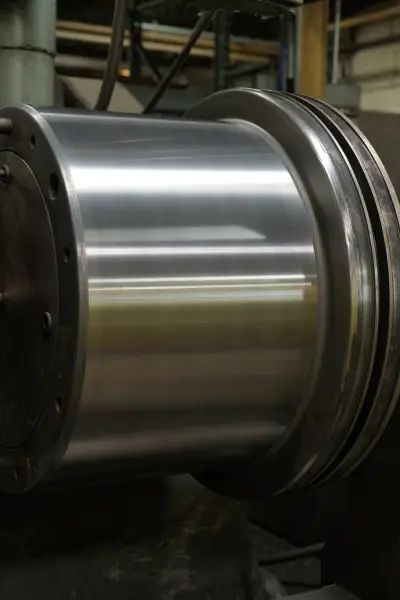

High Pressure Piston Diamond Grinding

Operating a High Pressure Piston Diamond Grinding

Hannecard - ASB Industries expert coating professionals can provide HVOF tungsten carbide spray coating services to nearly any substrate. We can also incorporate masking, tooling, and fixturing processes into our HVOF thermal spray methods for complete customization based on your project’s exact specifications.

What are Tungsten Carbide Coatings?

Tungsten carbide is a chemical carbide containing equal parts of tungsten and carbon atoms. It is approximately twice as strong as steel with double the density of steel—nearly midway between that of lead and gold. When applied to a substrate, the HVOF (high-velocity oxy fuel) Cemented Tungsten Carbide Coating immediately bonds to the surface, resulting in high bond strength and extreme wear resistance.

Contact ASB for more information regarding tungsten carbide applications and coating processes, or call ASB at 330-551-5217 and we will discuss your specific project requirements. Hannecard - ASB Industries is your trusted source for technologically advanced Tungsten Carbide Thermal Spray Services.

HVOF Tungsten Carbide Coating Benefits

The tungsten carbide thermal spray coating process produces tremendous amounts of kinetic energy into the powder particles. When these highly energetic particles strike the substrate, their velocity drops to zero and they absorb their kinetic energy, which causes them to bond instantly to the workpiece. Subsequent particles arrive almost simultaneously, rapidly building up the coating. This results in very dense and cohesive tungsten carbide coatings, some of the benefits that result from this process include:

- High Bond Strength

- Low Residual Stress

- Low Porosity (Typically Less Than 0.5%)

- High Wear Resistance

- Good Tungsten Carbide Corrosion Resistance based on binder chemistry

Tungsten Carbide Coating Process

Tungsten carbide coatings are achieved through the HVOF thermal spray process. Within this process, fuel gas and oxygen are combusted in a high-pressure chamber reaching temperatures up to 5,600°F (3,093°C). The resulting hot, high-pressure gas is ejected through a small-diameter nozzle and accelerated down a long barrel at supersonic speeds. Tungsten carbide powder (or another powder coating material, as your project requires) is injected into the nozzle, where the particles mix with the speeding gases, reaching velocities up to 3,000 feet per second.

Tungsten Carbide Material Properties

Tungsten carbide is a chemical carbide containing equal parts of tungsten and carbon atoms. Tungsten Carbide’s hardness level is comparable with corundum and can only be polished and finished with abrasives of superior hardness such as cubic boron nitride and diamond powder, wheels, and compounds.

In its basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments.

Tungsten Carbide Coatings Grain Size & Volume Fraction Management

Coating properties such as hardness, wear resistance surface finish, and strength depend primarily on the grain size and volume fraction of the tungsten carbide particles used in the HVOF thermal spray process. Therefore, HVOF tungsten carbide coatings can be adapted to provide the specific properties needed for an application by controlling the grain size of the tungsten carbide particles and their volume relative to cobalt and other binders.

HVOF Thermal Spray Equipment for Tungsten Carbide Coatings

At ASB Industries, tungsten carbide coatings are the most frequently-applied wear resistant surface treatments. With an array of HVOF thermal spray equipment at our disposal, we can choose the best feedstock for your application and ensure consistent production. Our HVOF thermal spray rooms are designed to accommodate a wide range of components, utilizing large turning capabilities and equipment including:

- Robots

- X-Y Gun Manipulators

- Overhead Cranes

- Custom-Built Fixtures for Repetitive Production

- Complex Masking Fixtures to Protect Uncoated Areas

Applications for Tungsten Carbide Coatings

Erosion, abrasion, and corrosion are factors that should be considered when choosing different chemistries and binder materials. Tungsten thermal spray powder coatings are typically used for extreme wear conditions. These can include:

- In-House Thermal Spray Technology: ASB Industries’ on-site and in-house thermal spray technology allows us to apply long lasting, grip-surface HVOF tungsten carbide coatings to roll surfaces used in different paper production processes. Using our flame spray equipment, we can adapt our carbide spraying parameters to best accommodate the quality and thickness of the paper being produced.

- Steels & Metals Production: Within steel and metals production, tungsten coatings and tungsten carbide welding coatings are widely used from ore production through finished product. A multitude of accepted applications show dramatically reduced maintenance costs and improved production quality.

- Power Generation Technologies: For power generation industries, where coal is the fuel source, components must be protected from extreme abrasion under demanding production seasonal schedules. Hannecard - ASB Industries has a wide variety of HVOF thermal spray coating solutions for mission-critical components.

- Custom Finishes: If your application requires a specific finish, Hannecard - ASB Industries can apply tungsten thermal spray powder coatings to varying surface finishes or from large to small components. Additionally, most applications can be ground from our diamond grinding and diamond super finishing equipment. Hannecard - ASB looks at each project where component size matters.

Contact Hannecard - ASB Industries for Tungsten Carbide Coatings

Our proven HVOF thermal spray technology enables us to fully customize our tungsten carbide spray coatings to meet your unique application and performance requirements. Submit your project to receive a custom price quote, or contact Hannecard - ASB Industries to discuss HVOF thermal spray coatings custom tailored to your equipment’s exact specifications.

.webp)