Cold Spray Coatings

High Pressure Cold Spray Services

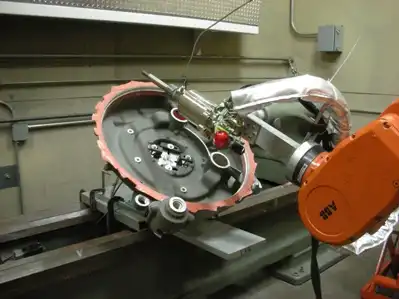

Repair on Magnesium Gear

Hannecard - ASB high pressure cold spray coatings can dramatically improve the performance of your equipment and extend its working life. Our turnkey cold spray coating services are customized to your project’s specifications, to give you the best solution for your application and performance requirements. Contact us to discuss cold spray coatings for your project or give us a call today at 330-551-5217.

Notable Characteristics of Cold Spray

Coating Technology

We utilize state-of-the-art cold spray technology to produce coatings with exceptional uniformity and repeatability. Our high pressure cold spray technology offers offer distinct advantages:

- Little to no oxidation during material build-up

- Dense coating

- Process can provide relatively high deposit efficiency

Groundbreaking technologies in the aerospace, medical and electronics industries have discovered the benefits of utilizing cold spray for coatings and additive manufacturing.

How Cold Spray Coatings Work

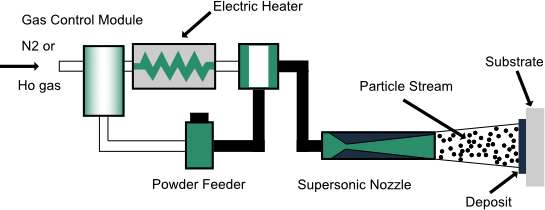

With high-pressure cold spray, coating materials aren't melted by a thermal energy source. Instead, energy from high-pressure gas allows injected powder material to reach critical velocity. The cold spray coating process utilizes supersonic nitrogen and/or helium gas jet that propels solid powder particles onto the workpiece at speeds as high as Mach 3 (900 m/s) to create both build up and surfacing layers. As a result, the particles form a strong and dense bond to the substrate.

Cold Spray Coatings from Hannecard - ASB

Hannecard - ASB has been researching and developing cold spray technology and equipment since 1996. Since we have been at the forefront of the development of this technology, customers from various industries have reached new levels of excellence with cold spray coatings. Numerous manufacturers and OEMs in the aerospace, medical, and electronics industries have already discovered the benefits; if we can meet the stringent requirements of these demanding markets, we can provide an effective cold spray coating solution for any application!

Discover the High Pressure Cold Spray Coating Edge

Discover the myriad ways in which your application can benefit from cold spray coatings. Submit a project or give us a call today at 330-551-5077 with your project requirements.

.webp)