Enhancement Coatings

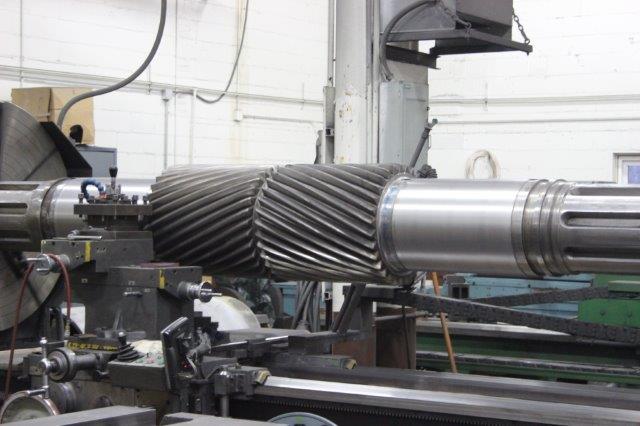

Pinion Gear Enhancement

Plasma Spray Process

Maintenance & Engineering Enhancements

Hannecard - ASB works closely with maintenance specialists and design engineers to find creative ways to extend equipment life to improve reliability of your entire operation. We provide all types of industrial enhancement coatings for thermal spray to help improve part performance, including:

- Ceramic coatings

- Flame spray coatings

- Tungsten carbide coatings

- And many more

Thermal Spray Coatings with OE Specifications

Depending on the application, performance coatings for thermal spray, enhancement coatings for thermal spray or hard coatings for thermal spray may be specified by an OE equipment designer, or requested by the end user to enhance equipment performance. In addition to providing extensive Thermal Spray capabilities, Hannecard - ASB can customize material selection for your proprietary processing needs. We can also specify one of the hundreds of commercially available materials for use in enhancing the performance of the equipment that makes your product.

Enhancement Coatings for Product Defect Prevention During Manufacturing

Surface defects, or irregularities in equipment, that come in direct contact with your product during the manufacturing process can leave marks and imperfections in the finished part. These problems can be corrected using enhancement coatings for thermal spray. Hannecard - ASB can meet your strictest processing requirements, providing pre- and post-treatment of enhancement coatings for thermal spray, which will add critical dimensional tolerances and surface finishes to your product.

Hard Coatings for Thermal Spray

Hard coatings for thermal spray reduces the cost of cast, forged or fabricated parts. Cast, forged or fabricated parts will have a longer working life by utilizing a less expensive base material that uses a thermal-sprayed hard coating on the wearing surface

Advantages of Thermal Spray

There are many advantages to using performance coatings for thermal spray, enhancement coatings for thermal spray or hard coatings for thermal spray, some of which include:

- Reduced cost

- Low heat input

- Versatility

- Thickness range

- Processing speed

Contact Hannecard - ASB Industries Today

Contact us today to learn more about our performance coatings for thermal spray, enhancement coatings for thermal spray or hard coatings for thermal spray services, or submit a project to receive a complimentary price quote.

.webp)